What are the 5 westgard rules – Embark on a journey to master the art of quality control in clinical laboratories with our comprehensive guide to the 5 Westgard Rules. These indispensable tools empower you to detect errors, identify trends, and ensure the accuracy and reliability of your laboratory results.

As we delve into each rule, you’ll gain a deep understanding of their formulas, interpretations, and practical applications. Discover how these rules safeguard your data, enabling you to make informed decisions and deliver exceptional patient care.

Introduction: What Are The 5 Westgard Rules

Westgard rules are a set of statistical criteria used in clinical laboratory quality control to detect and investigate errors in laboratory testing.

These rules are based on the assumption that laboratory data is normally distributed and that the mean and standard deviation of the data are stable over time. When these assumptions are met, the Westgard rules can be used to identify data points that are significantly different from the expected mean and standard deviation.

Significance of Westgard Rules

Westgard rules are an important tool for ensuring the accuracy and reliability of laboratory testing. By identifying errors in laboratory data, these rules can help to prevent patient misdiagnosis and mistreatment.

Westgard rules are also used to monitor the performance of laboratory instruments and reagents. By tracking the number of errors that occur over time, these rules can help to identify problems with laboratory equipment or procedures.

Westgard Rules: 1-2s

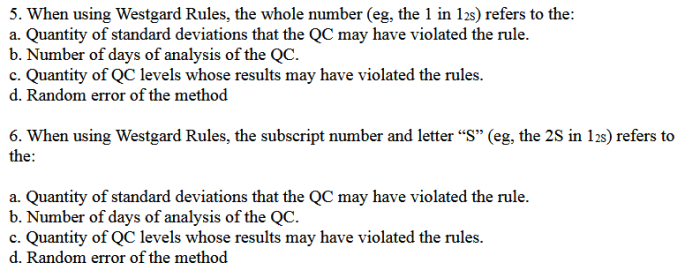

The 1-2s rule is used to detect random errors in a quality control process. It is based on the principle that random errors are more likely to occur in a single measurement than in consecutive measurements. The formula for the 1-2s rule is:“`|X- Xbar| / s <= 2 ``` where: * X is the measurement being evaluated - Xbar is the mean of the quality control data - s is the standard deviation of the quality control data If the result of the formula is less than or equal to 2, then the measurement is considered to be within control. If the result is greater than 2, then the measurement is considered to be out of control and may indicate a random error. The 1-2s rule is a simple and effective way to detect random errors in a quality control process. It is easy to apply and can be used to monitor any type of measurement data. Examples of how the 1-2s rule can be applied in practice: * A laboratory is monitoring the concentration of a chemical in a sample. The mean concentration of the chemical is 100 mg/L and the standard deviation is 5 mg/L. A single measurement of 105 mg/L is obtained. ``` |105 - 100| / 5 = 1 ``` Since the result of the formula is less than or equal to 2, the measurement is considered to be within control. * A manufacturing process is monitoring the weight of a product. The mean weight of the product is 100 grams and the standard deviation is 2 grams. A single measurement of 104 grams is obtained. ``` |104 - 100| / 2 = 2 ``` Since the result of the formula is greater than 2, the measurement is considered to be out of control and may indicate a random error.

Westgard Rules: R4s , What are the 5 westgard rules

The R4s rule is designed to detect systematic errors in laboratory testing.

It states that if the difference between the mean of the last two results and the mean of the previous two results exceeds 4 standard deviations, then a systematic error is likely present.

The formula for the R4s rule is as follows:

R4s = |(X1 + X2)

(X3 + X4)| / 2s

Where:

- X1 is the first result

- X2 is the second result

- X3 is the third result

- X4 is the fourth result

- s is the standard deviation of the control data

If the R4s value exceeds 4, then a systematic error is likely present and the laboratory should investigate the cause.

The R4s rule is a powerful tool for detecting systematic errors in laboratory testing. It is simple to use and can be applied to any type of laboratory data.

Here are some examples of how the R4s rule can be applied in practice:

- A laboratory is running a control sample for a chemistry test. The results of the last four controls are as follows:

- X1 = 100

- X2 = 102

- X3 = 98

- X4 = 96

- A laboratory is running a control sample for a hematology test. The results of the last four controls are as follows:

- X1 = 10,000

- X2 = 10,200

- X3 = 9,800

- X4 = 9,600

The mean of the last two results is (100 + 102) / 2 = 101.

Knowing the 5 Westgard rules is essential for understanding laboratory quality control. For those preparing for the APUSH exam, a comprehensive practice test like unit 3 apush practice test can help reinforce these concepts. By applying the Westgard rules, you can identify and correct errors in laboratory testing, ensuring accurate results.

Therefore, understanding the 5 Westgard rules is crucial for both laboratory professionals and students.

The mean of the previous two results is (98 + 96) / 2 = 97.

The difference between the two means is 101 – 97 = 4.

The standard deviation of the control data is 2.

The R4s value is 4 / 2(2) = 1.

Since the R4s value is less than 4, there is no evidence of a systematic error.

The mean of the last two results is (10,000 + 10,200) / 2 = 10,100.

The mean of the previous two results is (9,800 + 9,600) / 2 = 9,700.

The difference between the two means is 10,100 – 9,700 = 400.

The standard deviation of the control data is 100.

The R4s value is 400 / 2(100) = 2.

Since the R4s value is greater than 4, there is evidence of a systematic error and the laboratory should investigate the cause.

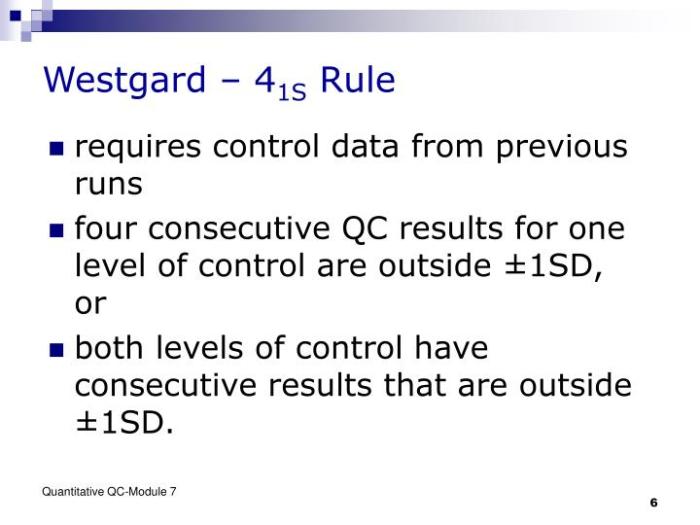

4. Westgard Rules

4-1s

The 4-1s rule is designed to detect shifts in the mean of a distribution. It states that if four consecutive data points are all on the same side of the mean and the last point is at least 1 standard deviation (SD) away from the mean, then a shift in the mean has occurred.

The formula for the 4-1s rule is:“`|x

μ| ≥ 1SD

“`where:* x is the data point

- μ is the mean

- SD is the standard deviation

The 4-1s rule is a simple and effective way to detect shifts in the mean. It is often used in quality control to monitor the performance of a process. For example, if a company is monitoring the weight of a product, they could use the 4-1s rule to detect if the mean weight of the product has shifted.Here

are some examples of how the 4-1s rule can be applied in practice:* A laboratory is monitoring the concentration of a chemical in a solution. The mean concentration is 100 mg/L and the standard deviation is 5 mg/L. If the laboratory obtains four consecutive readings that are all below 95 mg/L, then the 4-1s rule would be triggered and the laboratory would investigate to determine if the mean concentration has shifted.A

manufacturing company is monitoring the weight of a product. The mean weight is 100 grams and the standard deviation is 5 grams. If the company obtains four consecutive readings that are all above 105 grams, then the 4-1s rule would be triggered and the company would investigate to determine if the mean weight has shifted.The

4-1s rule is a valuable tool for detecting shifts in the mean. It is simple to use and can be applied to a wide variety of data.

Westgard Rules: 10x and 13x

The 10x and 13x rules are statistical guidelines used to identify extreme outliers in a dataset. They are based on the assumption that the data follows a normal distribution.

The 10x rule states that any data point that is more than 10 standard deviations from the mean is considered an outlier.

The 13x rule states that any data point that is more than 13 standard deviations from the mean is considered an extreme outlier.

These rules can be used to detect extreme outliers that may be due to errors in data collection or analysis. For example, if a laboratory test result is more than 10 standard deviations from the mean, it may be due to a sample contamination or a faulty instrument.Here

is an example of how the 10x and 13x rules can be applied in practice:

A laboratory is testing the blood glucose levels of a group of patients. The mean blood glucose level is 100 mg/dL, and the standard deviation is 10 mg/dL. According to the 10x rule, any blood glucose level that is more than 100 + (10 – 10) = 200 mg/dL is considered an outlier.

According to the 13x rule, any blood glucose level that is more than 100 + (10 – 13) = 230 mg/dL is considered an extreme outlier.

If a patient’s blood glucose level is 250 mg/dL, it would be considered an extreme outlier according to both the 10x and 13x rules. This result would likely be investigated further to determine if there was an error in data collection or analysis.

Implementation and Interpretation

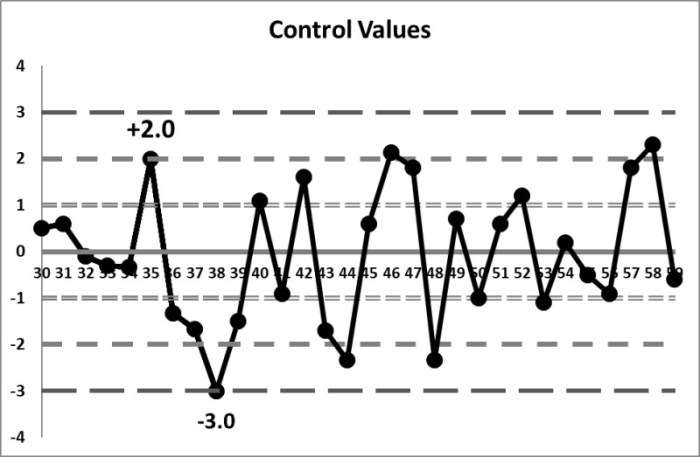

Westgard rules are implemented in clinical laboratories to monitor the quality of analytical processes. They are applied to control charts, which are graphical representations of data that track the performance of a laboratory test over time.

To interpret the results of Westgard rule applications, it is important to understand the concept of statistical significance. A statistically significant result is one that is unlikely to occur by chance alone. In the context of Westgard rules, a statistically significant result indicates that there is a problem with the analytical process.

Corrective Actions

When a Westgard rule is violated, it is important to take corrective action to identify and resolve the problem. The specific corrective action will depend on the nature of the rule violation.

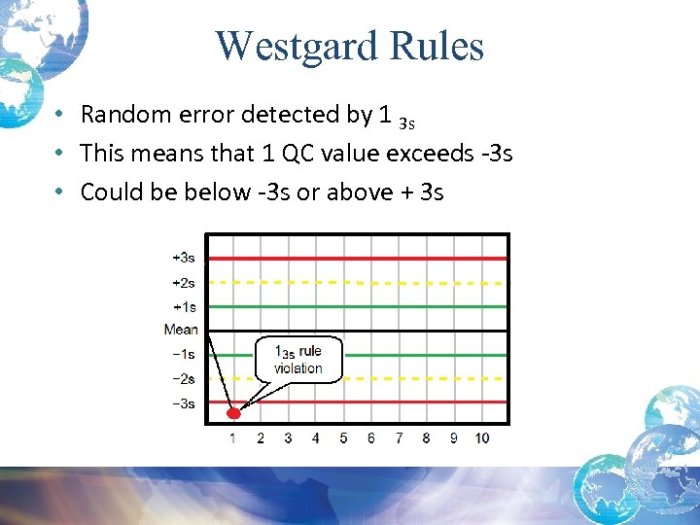

- Rule 1 violation:This indicates a random error. No corrective action is necessary.

- Rule 2 violation:This indicates a shift in the mean of the process. The laboratory should investigate the cause of the shift and take corrective action to bring the mean back into control.

- Rule 3 violation:This indicates a trend in the data. The laboratory should investigate the cause of the trend and take corrective action to stop the trend.

- Rule 4 violation:This indicates that the data is not normally distributed. The laboratory should investigate the cause of the non-normality and take corrective action to bring the data back to a normal distribution.

- Rule 5 violation:This indicates that there is a problem with the precision of the process. The laboratory should investigate the cause of the precision problem and take corrective action to improve the precision.

Limitations and Considerations

While Westgard rules are valuable for quality control in laboratory testing, they do have certain limitations and considerations to keep in mind.

The accuracy and reliability of these rules can be affected by several factors, including:

Sample Size

- The number of data points used to establish the control limits can impact the sensitivity of the rules.

- Smaller sample sizes may lead to wider control limits, making it more difficult to detect shifts or trends.

Data Distribution

- The distribution of the data should be approximately normal for Westgard rules to be effective.

- Non-normal data distributions can lead to false positives or negatives.

Measurement Error

- Measurement errors can introduce variability into the data, making it harder to identify true shifts or trends.

- It’s important to minimize measurement errors through proper calibration and maintenance of equipment.

Recommendations

- To address these limitations, it’s recommended to use the appropriate number of data points for establishing control limits.

- Assess the normality of the data distribution and consider using alternative statistical methods for non-normal data.

- Implement measures to minimize measurement errors and ensure the accuracy and precision of the data.

FAQ Compilation

What is the purpose of the 1-2s rule?

The 1-2s rule detects random errors by identifying values that deviate significantly from the expected range.

How does the R4s rule differ from the 1-2s rule?

The R4s rule focuses on detecting systematic errors, which occur when a series of consecutive values fall outside the expected range.

What is the significance of the 10x and 13x rules?

The 10x and 13x rules are designed to identify extreme outliers, which may indicate contamination or other significant issues.