Embark on a comprehensive exploration of chapter 3 containers tools mechanics and safe work practices, unlocking the intricacies of container handling and empowering you with the knowledge and skills to navigate this crucial aspect of the industry.

From understanding the fundamental components of containers to mastering the mechanics of handling them safely and efficiently, this chapter provides a thorough foundation for professionals seeking to excel in container handling operations.

Containers and Their Components

Containers play a pivotal role in the modern shipping industry, enabling efficient and secure transportation of goods. They are standardized units that facilitate the movement of cargo across various modes of transport, including ships, trains, and trucks.

Essential components of containers include:

- Frame:Provides structural support and strength.

- Walls:Enclose the container and protect the contents.

- Roof:Covers the container and prevents water damage.

- Doors:Allow for loading and unloading.

- Twistlocks:Secure containers to ships or other carriers.

- Identification markings:Include container number, size, and other relevant information.

Containers come in various types, each with unique characteristics:

- Dry containers:General-purpose containers for non-perishable goods.

- Refrigerated containers:Equipped with temperature control for perishable goods.

- Open-top containers:Designed for bulky or oversized cargo.

- Flat-rack containers:Used for transporting heavy or oddly shaped items.

- Tank containers:For transporting liquids or gases.

Tools for Handling Containers

Safe and efficient container handling requires specialized tools. These tools assist in lifting, moving, and securing containers, ensuring the safety of personnel and cargo.

Common tools include:

- Spreaders:Attach to cranes and lift containers.

- Forklifts:Used to move containers on land.

- Straddle carriers:Vehicles that straddle containers and transport them.

- Top handlers:Lift and move containers from above.

- Sideloaders:Load and unload containers from the side.

- Twistlock wrenches:Secure containers to carriers.

- Tie-down systems:Prevent containers from shifting during transport.

Using appropriate tools is crucial for safe container handling. Proper training and adherence to safety guidelines are essential.

Mechanics of Container Handling: Chapter 3 Containers Tools Mechanics And Safe Work Practices

Understanding the mechanics of container handling is vital for ensuring safety and efficiency.

Lifting involves using spreaders attached to cranes or top handlers to raise containers. Load distribution and stability are crucial, requiring careful consideration of the container’s center of gravity.

Transporting containers requires selecting the appropriate equipment based on the mode of transport and distance. Forklifts, straddle carriers, and trucks are commonly used.

Stacking containers involves placing them one on top of another. Proper stacking techniques, such as the use of corner castings and twistlocks, ensure stability and prevent damage.

Safe Work Practices for Container Handling

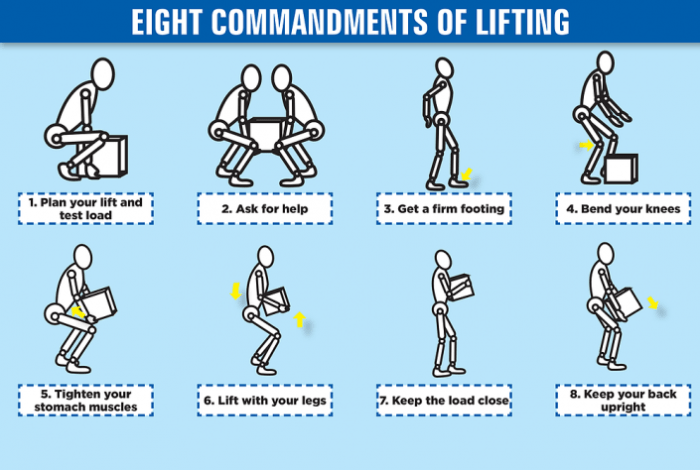

Establishing and adhering to safe work practices are paramount in container handling operations.

Potential hazards include:

- Falling objects

- Tipping or shifting containers

- Pinch points

- Electrical hazards

Mitigating these hazards requires:

- Proper training and supervision

- Using appropriate tools and equipment

- Adhering to load limits

- Inspecting containers and equipment regularly

- Wearing appropriate personal protective equipment

- Establishing clear communication protocols

Personnel involved in container handling have specific roles and responsibilities, including:

- Supervisors: Ensure safety and compliance.

- Crane operators: Lift and move containers.

- Dockworkers: Load and unload containers.

- Truck drivers: Transport containers.

Essential Questionnaire

What are the key components of a container?

The essential components of a container include the frame, corner castings, twistlocks, doors, and roof.

What is the importance of using appropriate tools for container handling?

Using appropriate tools ensures the safe and efficient handling of containers, minimizing the risk of damage or injury.

What are the fundamental mechanics involved in container handling?

The fundamental mechanics include lifting, transporting, and stacking containers, considering load distribution and stability.

Why is it crucial to adhere to safe work practices when handling containers?

Adhering to safe work practices minimizes the potential hazards associated with container handling, such as falls, crushing injuries, and spills.

What are the benefits of training and certification for container handling personnel?

Training and certification provide personnel with the knowledge and skills to handle containers safely and efficiently, reducing risks and enhancing productivity.